Sugar Supply Chain: From Cane to Container – Revolutionizing with Smart IT Solutions

Introduction

One of the most elaborate and dynamic networks in the world for food and beverages is the sugar supply chain. Every stage—from lush landscapes with sugarcane fields to refined sugar reaching into retail containers—involves many players, with intricate logistics and critical quality checkpoints. Inefficiencies, losses, and major compliance challenges are the results from manual management or using antiquated systems.

That’s where advanced IT and digital supply chain solutions enter the picture. New technologies now modernize how sugar manufacturers, refiners, distributors, and exporters work by introducing real-time insight, predictive analytics, and process automation into a business that was largely controlled manually.

This blog considers the complete value chain for sugar—from cane to container—and how our latest integrated IT system can transform each one of those steps in an efficient, transparent, and profitable way around the world.

1. Overall Context of Sugar Supply Chain

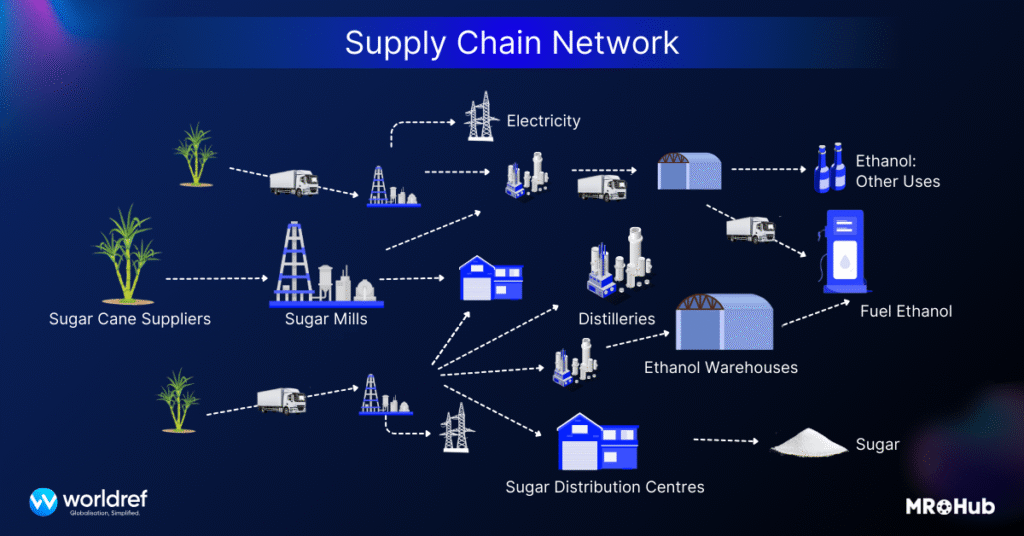

The supply chain for sugar starts right from production at the level of the sugarcane or sugar beet raw material down to when refined sugar reaches the final consumer or the industrial buyer.

Key Stages Include:

- Cultivation & Harvesting: These involve the growing of sugarcane/beet and then being harvested when the crop has reached its maturity.

- Transportation to Mills: Deliveries of raw materials into the processing facilities should be done in the shortest time possible to reduce loss of sucrose.

- Primary Processing (Crushing & Extraction): The juice is extracted and processed into raw sugar.

- Refining & Packaging: Refine raw sugar into other forms, accordingly package for different purposes.

- Storage & Distribution: Logistics, warehousing, and shipment management in a global perspective.

Each of these phases is accompanied by huge flows of data, coordination of resources, and close monitoring of quality and compliance. Without an equally high-capacity IT backbone in managing the said complexity, this could easily lead to bottlenecks, errors, and waste of resources.

2. Role of IT in Modern Sugar Supply Chain

Digitalization has revived the operational functions of the firms in the sugar industry. Application of supply chain management software developed for the sugar industry will help in effective reduction of operational costs and increase data accuracy with added traceability.

Our Sugar Supply Chain Management IT System Comes With:

- End-to-End Traceability: From the field to shipment, know where every grain of sugar goes.

- Real-Time Analytics: Provides instant insights into production, transportation, and demand patterns.

- Automation of Work Flow: No more manual entry and complicated approval and logistics.

- Integration Capabilities: Seamless integrations with ERP, IoT sensors, and logistics partners.

- Compliance Management: The company shall abide by all international standards of food safety and export.

It provides sugar companies with a way to achieve operational excellence by responding to the growing consumer and regulator demands for more transparency and quality.

3. From Cane to Container: A Step-by-Step Transformation

Stage 1: Cultivation & Farm Management

Sugarcane crops are highly intensive in terms of soil requirements, irrigation, and harvesting time. Our integrated IT system from AgriTech empowers sugar producers in manifold ways:

- Integration with IoT sensors will provide continuous monitoring of soil moisture, temperature, and crop health.

- AI-driven analytics can predict the best harvesting windows.

- Record input costs, applications of fertilizer, and yield estimates in real time.

- This enables the field supervisors to update the data of the plantations using their mobiles.

It ensures better allocation of resources, higher yields, and consistent quality of the raw material going into processing.

Stage 2: Sourcing and Transportation of Raw Materials

Cane or beet needs to be moved quickly to the mills once it is harvested. Delays may dent sugar recovery rates. Our Logistics Optimization Module ensures that:

- Optimizing routes using GPS and real-time traffic information.

- Automated scheduling of dispatches with vehicle tracking.

- Identification of every batch using a barcode or QR code.

- Integrated communication amongst farmers, drivers, and mills.

This saves on transport time, fuel costs, and losses, while the raw material also arrives in optimum condition at the processing plant.

Stage 3: Milling and Crushing Operations

After harvesting, the cane is washed, crushed, and processed into raw sugar at the mill. This is an area of the process that requires a great amount of precision and monitoring.

Our Mill Management IT Platform delivers:

- Real-time monitoring of crushing performance, temperature, and output.

- Predictive maintenance notifications originate with critical machinery equipped with IoT sensors.

- Energy management dashboards to optimize steam, power, and fuel consumptions.

- Automate the reporting on production, losses, and quality parameters.

With this functionality, plant managers will gain complete visibility into production efficiency, downtime, and cost per ton to ensure better profitability.

Stage 4: Refining & Packaging

Refining is the process of changing raw sugar into various forms like white refined sugar, brown sugar, or liquid sugar. During this process, consistency and purity are everything.

Our Refinery Automation and Quality Control Software provides:

- Batch tracking of all input and output materials.

- Automation of refining parameter control, such as temperature and crystallization time.

- Integration with laboratory test systems for quality verification.

- Automate the packaging line, including the generation of barcodes to enable traceability.

This will ensure that each container of packed sugar is of good quality and meets all the international standards required, apart from eliminating reworks and callbacks.

Stage 5: Storage, Distribution, and Export

After packaging, sugar is stored, distributed, or exported to the clients all over the world. This stage also involves logistics coordination and documentation.

Our IT Solution for Logistics and Export Management includes:

- Automatically track your inventory for intelligent management of the warehouse.

- Demand forecasting balances production against market need.

- Integration with customs and export documentation systems.

- End-to-end visibility into the shipment container all the way from port to customer.

The outcome is fewer stockouts, quicker delivery times, and improved coordination across the global sugar network.

4. Key Specifications of Our Sugar Supply Chain IT System

| Feature | Specification | Benefit |

|---|---|---|

| Platform Type | Cloud-based, On-premise hybrid | Flexible deployment and scalability |

| Data Integration | API, ERP, IoT, GPS, RFID | Seamless flow of data across departments |

| Analytics | AI-driven dashboards, predictive reports | Informed data-driven decisions |

| Security | End-to-end encryption, role-based access | Secure, compliant data management |

| Compliance | ISO 22000/HACCP, FDA & EU Export Standards | Global operational readiness |

| Automation | Workflow automation with machine integration | Reduced manual effort and improved accuracy |

| Mobile App | iOS & Android | Real-time field and logistics updates |

| Customization | Industry-specific modules | Suited for sugar operations |

| Support | 24/7 Global Support | Dependable assistance anywhere, anytime |

These specifications will make our solution a comprehensive digital backbone for sugar producers, refiners, and distributors in their quest to attain sustainable growth.

5. Why Choose Our IT Solution for the Sugar Supply Chain?

1. Industry Expertise

Regarding the sugar industry, our solution covers very specific challenges from sucrose losses to in-depth moisture analysis and crop variability.

2. Global Scalability

Whether your organization operates one mill or a collection of refineries around the world, this innovative, cloud-based platform scales up or down with the size of your business.

3. Real-Time Decision Making

With integrated analytics, managers can take action on insights in real time and stay ahead of problems before they become major ones.

4. Better Profitability

Such factors as optimized resources, logistics, and efficiency in production may have implications in regard to the cost cuts and profit margins of the companies concerned.

5. Sustainability & Compliance

ESG objectives can be achieved by embedding sustainability metrics and managing compliance.

6. The Digital Future of Sugar Supply Chains

Presently, the sector has started its transformation towards smart factories and digital supply networks. Undoubtedly, IoT, AI, Blockchain, and Machine Learning have reinvented the way sugar is grown, processed, and distributed.

Key Innovations Driving the Future:

- IoT & Sensor Integration: Smart sensors collect real-time data on everything from soil moisture to machine vibration in mills and farms to avoid inefficiency.

- Blockchain Traceability: The entire supply chain, right from cane harvesting to the export of sugar, becomes tamper-proof, thus building greater transparency and trust among consumers and regulators alike.

- AI-Driven Forecasting: Predictive AI determines production output, weather impact, and demand fluctuations to make correct, timely planning of the supply chain.

- Cloud Collaboration: Information can be shared instantly between suppliers, distributors, and exporters through cloud platforms to avoid delays and paperwork.

All these technologies will be part of this system in creating a future-ready platform—one that grows with your business.

7. Benefits of Digitalizing the Sugar Supply Chain

- Operational Efficiency: Automate manual workflows to minimize human errors.

- Cost Reduction: Optimizing energy, transportation, and manufacturing costs.

- Faster Time-to-Market: With streamlined logistics, the deliverables are faster.

- Data Transparency: All processes are tracked, verified, and auditable.

- Customer Confidence: Traceable sugar creates trust and brand loyalty.

- Sustainability: Follow the carbon footprint closely and use all resources efficiently.

These benefits will position your company as a leader within sustainable and digital sugar production, prepared to meet or even exceed the expectations of the world market.

8. Implementation & Integration

Our IT solution seamlessly integrates into your existing infrastructure.

We provide:

- Step-by-step deployment assistance for mills and refineries.

- Employee training to adapt to digital workflows.

- Custom dashboards based on your operational KPIs.

- Continuous updates and global technical support.

The implementation can be done in different phases, starting from simple modules tracking logistics items to a fully integrated solution with IoT and analytics systems.

9. Case Example (Hypothetical)

A multinational sugar manufacturer implemented our IT system at its three refineries. Within six months:

- Production efficiency improved by 18%.

- Transportation delays were reduced by 25%.

- Inventory wastage reduced by 30%.

- Quality consistency achieved at 99.5% accuracy.

They gained better control, compliance, and visibility through the digitalization of the complete value chain and thereby realized measurable ROI and market expansion.

10. Conclusion: Your Digital Partner in the Sugar Supply Chain

From cane to container, the journey of sugar is complex—but it can be seamless, transparent, and profitable with the right technology.

Our Sugar Supply Chain Management IT System empowers producers, refiners, and exporters to gain end-to-end visibility, reduce costs, and deliver top-quality sugar products anywhere in the world.

In an increasingly digitalized world economy, one outsteps the others only by embracing novelty. With our advanced IT solutions, your sugar business doesn’t just cope—it leads.

Ready to Modernize Your Sugar Supply Chain?

Contact us today to learn how our integrated IT systems can transform your operations from field to finished product.

Refined Sugar Export to South Africa – Buy in Bulk – Sugar export South Africa