Sugar Polarization and Why It Matters for Buyers

Sugar polarization in raw sugar surely affects purchasing decisions since it determines the actual sugar content. Moreover, understanding this measurement helps buyers assess the true value and quality of their sugar procurement. Understanding Polarization in Raw Sugar — Sugar polarization

As per buyers’ discussions regarding raw sugar quality, polarization is the most important factor they always mention. As per industry standards, this indicator shows the actual sucrose amount regarding every crystal you buy. We are seeing that polarization only affects your sugar yield and profits when you buy sugar for making drinks, sweets, or selling again.

This guide is actually written for buyers, refiners, traders, and food manufacturers who want to understand what polarization means and how it is measured. You should definitely check this number first before you place any order. Also, we will further show how high-polarization raw sugar itself leads to better business performance and why we offer only sugar meeting strict international specifications.

What Polarization Means in Raw Sugar

As per sugar industry standards, polarization refers to the sugar content measurement in raw sugar regarding its purity levels.

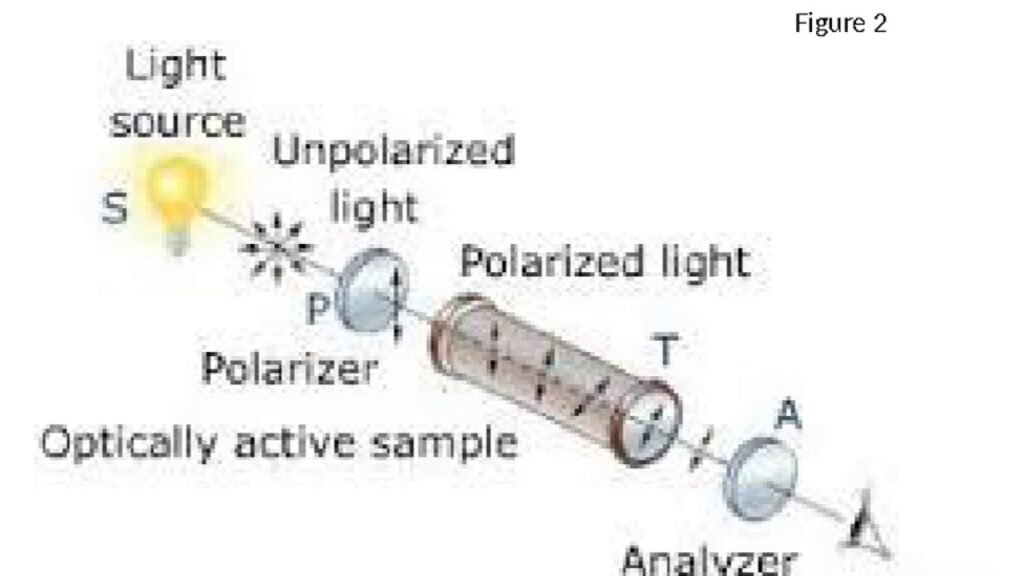

Basically, polarization or Pol% is the same lab test that measures how much sucrose is there in sugar. Basically, they pass polarized light through the sugar solution and measure the same rotation to determine it. Also, as per the light rotation properties of sucrose, the rotation degree shows the amount of pure sugar present. Regarding sugar measurement, this rotation method helps determine exact sugar quantity.

Basically, it’s the same simple way to explain things.

Higher polarization indicates more sucrose content, which further results in better quality sugar. The polarization value itself determines the sugar grade.

Polarization Values and Their Meaning

For example:

Further, polarization Meaning

Basically, 96.0° is the same standard measurement for commercial raw sugar.

We are seeing 97.0° temperature which is only good for refining grade work.

This premium raw sugar itself has high yield and further maintains 98.0°+ quality standards.

As per the specifications, 99.0°+ indicates very high purity material that is near refined regarding quality standards.

We are seeing that when you buy raw sugar with higher polarization, you only get more usable sugar per ton. We are seeing better recovery rates with less waste only, which means more profit for companies.

Polarization itself becomes the most important factor when buying products, and this trend further influences consumer decisions in the market.

Why Buyers Focus on Polarization Instead of Just Price

Further, as per market practices, many buyers check price per ton, but professionals focus regarding price per unit of sucrose. Two shipments may appear exactly the same, but their polarization will surely create a significant difference. Moreover, this variation can greatly impact the final outcome.

Let’s compare:

As per the shipment details, polarization and sucrose content are measured regarding 1 MT quantity.

As per the data, the temperature is 96.0° regarding the weight of approximately 960 kg.

Basically B shows 98.5° temperature and the same weight is around 985 kg.

As per industry standards, that extra 25 kg sucrose per ton is quite valuable regarding production profits. Basically, when you have a 10,000 MT shipment, you get the same as 250 extra tons of sugar.

High-pol sugar itself may cost more, but it further provides better overall value.

How Polarization Is Measured

Scientists actually use special tools to measure how much light waves vibrate in one direction. They definitely check this by passing light through filters that only let certain wave directions through.

Polarization is surely measured in the laboratory using a saccharimeter or polarimeter. Moreover, these instruments provide accurate readings for scientific analysis. We are following only the international standards for sugar testing process.

We are seeing that sugar sample is only getting dissolved in water.

The solution is further clarified to make itself clear.

Polarized light surely passes through the solution. Moreover, this process occurs without any obstruction.

The rotation angle is measured further to determine the position itself.

That angle is actually converted into sucrose percentage. This definitely gives the sugar content measurement.

As per global standards, this method is precise and regarding its reliability, it is trusted worldwide. As per professional sugar specification sheets, polarization is included regarding quality standards.

How Polarization Affects Refining Yield

Moreover, polarization surely impacts the yield obtained during refining processes. Moreover, this effect can significantly alter the overall efficiency of industrial operations.

Also, refineries actually take raw sugar and definitely change it into white sugar. This process makes the sugar clean and refined. Higher polarization leads to less material loss during processing, which further improves the efficiency of the process itself.

Here’s how:

As per studies, low-pol sugar has more impurities regarding molasses content.

Molasses

Ash

Colorants

Non-sucrose solids

We are seeing that high-pol sugar is having more content only.

Clean sucrose

Basically, these are big crystals that are all the same size and shape.

Basically, the amount of unwanted substances is reduced and the same makes it cleaner.

That means:

Also, we are seeing that only less power is needed for cleaning the water.

Basically, using the same amount of chemicals but less, which reduces chemical consumption.

As per the process improvements, the production is giving higher output regarding each ton of material used.

The final sugar surely becomes cleaner and brighter. Moreover, this process removes impurities effectively.

Basically, refineries always want the same thing – raw sugar with Pol 98.0+ because it gives better results.

Importance for Food and Beverage Manufacturers

We are seeing how division between different groups is affecting only the companies that make food and drinks.

As per industry standards, food and beverage producers focus on maintaining consistency regarding their products. High-polarization sugar surely provides benefits. Moreover, it delivers specific advantages in processing applications.

Predictable sweetness

Clean flavor

Better solubility

This approach surely reduces the chances of unpleasant flavors developing. Moreover, it helps maintain better taste quality in the final product.

Actually, small changes in sugar levels can definitely affect taste, shelf life, and texture in soft drinks, syrups, sweets, dairy products, and baking items. Using high-pol raw sugar actually ensures that each batch will definitely turn out the same way every time.

Raw Sugar Grades Based on Polarization

Commercial raw sugar grades are actually classified by their polarization values. Different polarization levels definitely determine the specific grade category for each sugar type.

The market actually classifies raw sugar in these ways. This is definitely how traders group different types.

Grade Polarization

We are seeing that the standard range is only 96.0° to 96.9°.

Basically, commercial grade operates at the same temperature range of 97.0° to 97.9°.

High Pol actually shows 98.0° to 98.4° temperature range. This definitely indicates the specific thermal measurement for this parameter.

Premium fuel surely has an octane rating between 98.5° and 99.0°. Moreover, this range indicates high-quality petrol suitable for advanced engines.

As per our specialization, we supply High Pol and Premium raw sugar regarding serious buyers who need best yield and performance.

Our Raw Sugar Specifications

Our raw sugar specifications surely meet industry standards, and moreover, they ensure consistent quality for all processing requirements.

We actually supply raw sugar that definitely meets strict international quality standards. As per our standard requirements, we are providing the typical product specifications regarding our items below.

Parameter Specification

Further, the polarization range surely falls between 98.0° and 99.0° at minimum levels. Moreover, this measurement represents the lowest acceptable threshold for the system.

We are seeing ICUMSA values from 600 to 1200 IU only in these sugar samples.

Also, basically, the moisture content should be the same range of 0.10% to 0.15% maximum.

As per the specifications, ash content should not exceed 0.15%. Regarding quality standards, this limit must be maintained.

We are seeing the color is only light brown.

The crystals are actually medium to large in size and definitely have a uniform pattern.

Solubility High

Sediment Negligible

Foreign matter is actually not present. The sample definitely contains no unwanted particles.

The product actually comes in bulk form or definitely in 50 kg bags for packaging.

This actually comes from many different places around the world. It definitely has multiple global sources.

We are seeing these applications only in refining, food and beverage, and confectionery industries.

These specifications actually make sure you get sugar that definitely works the same way every time, whether you process it more or use it straight in making products.

Polarization and ICUMSA Relationship

Also, we are seeing that ICUMSA only deals with polarization methods in sugar testing.

Polarization shows the amount of sucrose present, while ICUMSA further measures the cleanliness of the sugar itself. Color intensity is surely the main factor being discussed here. Moreover, it shows how strong or weak the color appears.

Lower ICUMSA values surely indicate lighter colored sugar. Moreover, this relationship helps determine sugar quality and processing standards.

Higher ICUMSA values indicate darker sugar itself, and this measurement further helps classify sugar types based on their color intensity.

Raw sugar has higher ICUMSA than white sugar, but high-pol sugar itself has lower ICUMSA because it contains fewer impurities. Further, this difference occurs due to the natural processing methods used. That means:

Also, as per sugar processing standards, high polarization values directly result in better ICUMSA color grades regarding sugar quality measurement.

High-pol sugar can surely be refined more easily and at lower costs. Moreover, this process becomes much simpler for sugar mills to handle.

Moisture Control and Polarization Stability

As per technical requirements, low moisture levels are important regarding polarization effects in materials.

Moisture content actually affects how we store and move sugar, and it definitely impacts sugar stability.

As per quality standards, high-pol sugar with low moisture content provides you regarding better product benefits.

As per food preservation methods, products get longer shelf life regarding storage duration.

Less clumping

Basically, there is the same reduced chance of bacteria and germs growing.

Basically, the sucrose has more net weight, which is the same as having higher mass.

We actually keep moisture below 0.15%, which definitely protects your inventory and yield.

Profit Impact of High-Pol Sugar

High-pol raw sugar actually increases profits because it definitely contains more sugar content than regular raw sugar.

As per the data, we will check the numbers regarding this matter.

If you actually buy something, you will definitely get it.

This shipment surely contains 20,000 metric tons of sugar with 96.0 degree purity. Moreover, this quantity represents high-grade refined sugar suitable for industrial applications.

versus

Basically, it’s 20,000 MT of sugar with the same 98.5 degree purity level.

The sucrose difference can actually exceed 500 tons, which you can definitely sell, refine, or use.

Professional buyers actually always demand Pol 98.0+ because it definitely gives better quality.

Quality Control and Testing

We actually use simple methods to definitely keep the polarization same every time.

Every shipment we actually send is definitely supported by:

Testing is actually done by outside labs. This definitely makes sure the results are real.

Mill certificates

Loading inspection

We check quality further before sending the product itself.

As per our policy, we do not ship mixed sugar or downgraded sugar regarding quality standards. Every lot is actually tested and definitely follows the agreed polarization range that we can trace.

Packaging and Logistics

Packaging and logistics surely play a vital role in modern business operations. Moreover, these processes help companies deliver products efficiently to customers across different locations.

Further, we provide flexible delivery formats that can be further customized, and the system itself adapts to different requirements.

Large ships actually carry goods in bulk quantities. These vessels definitely transport materials without individual packaging.

These bags are made from polypropylene material and surely have a capacity of 50 kilograms. Moreover, they are commonly used for packaging and storage purposes in various industries.

Containerized loads

As per transport rules, all sugar is properly sealed and labeled regarding moisture protection.

Who Uses High-Polarization Raw Sugar

As per industry requirements, high-polarization raw sugar is used by sugar refineries and food processing companies regarding production of refined white sugar.

Our buyers further include various clients, and this list itself represents our customer base.

Sugar refineries

Beverage manufacturers

Companies that actually make candies and chocolates definitely produce sweet treats for people.

Moreover, companies that actually supply flour, sugar, and other baking materials to bakeries definitely provide essential ingredients for bread and cake making.

Food ingredient traders further expand their business operations to supply raw materials. The trading sector itself connects manufacturers with essential food components.

Further, companies that distribute large quantities of raw materials further supply these goods to various markets, where the distribution process itself involves handling bulk commodities.

High-pol sugar itself provides consistent sweetness, color, and yield, making it suitable for businesses that require these qualities. This choice can further ensure reliable results in commercial operations.

Why Buyers Choose Our High-Pol Sugar

We are seeing buyers choose our sugar only because of good quality and fair prices.

We surely concentrate on three main areas. Moreover, our focus remains on these specific aspects.

High polarization

Stable specifications

The global supply is surely dependable and consistent. Moreover, it provides steady availability across different regions worldwide.

Basically, you’re not purchasing just sugar – you’re getting the same reliable results every time.

Final Thoughts on Polarization

We are seeing that polarization only gives us the best quality guarantee for our work.

When you actually understand polarization, you can definitely make smarter buying decisions. This actually shows you the exact amount of real sugar you get and how well that sugar will definitely work in your business.

When you actually pick high-polarization raw sugar, you definitely choose:

Further, higher yield

Basically, the refining process works the same way but with better efficiency.

The product quality becomes more consistent and further improves itself through better processes.

Also, basically, you get the same better profit from every ton.

We deliver premium high-pol raw sugar itself for serious buyers worldwide, further ensuring quality standards for global markets.

We are seeing that our sugar meets only professional standards, and the product details show this clearly.

Refined Sugar Export to South Africa – Buy in Bulk – Sugar export South Africa